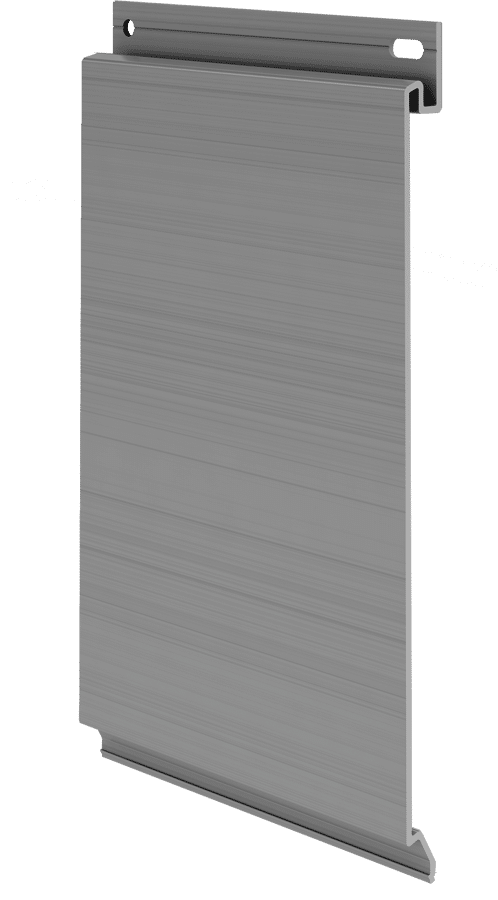

Xtral offers a range of inspiring interlocking façade systems for the rainscreen façade market, utilising this non-combustible solution on your next project will deliver design flexibility.

A1/A2 cladding panels

Lightweight and strong

Built to last the test of time

All-in-one cladding solutions

Rainscreen Cladding Support

Non-combustible solutions

Expertise, Support, & Guidance

Working perfectly together

This is a block of text. Double-click this text to edit it.