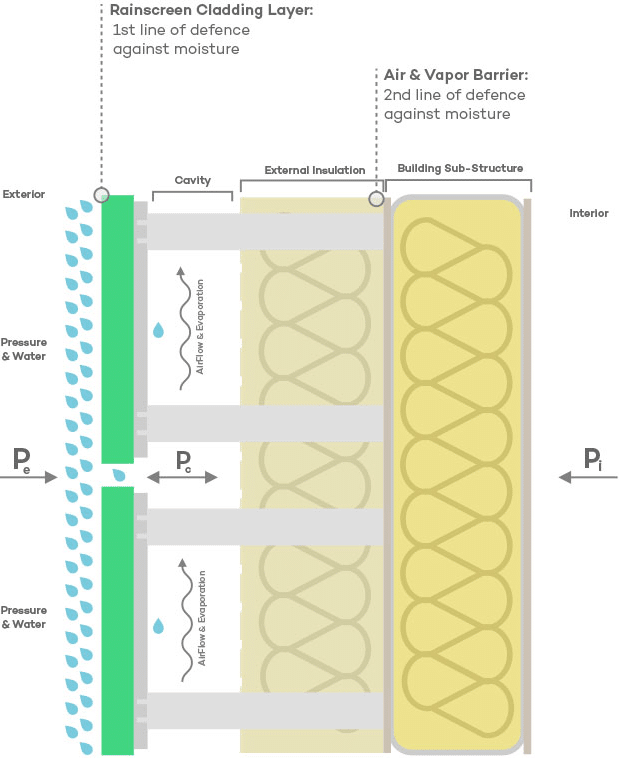

Valcan are experts in rainscreen cladding and one of the largest stockists of ACM in the UK. We pride ourselves on fast lead times and have a wide distributor network to deliver and manufacture composite panelling. We supply large and small projects at highly competitive prices. We offer a full-colour matching service and can provide samples of all our finishes. Thanks to our vast experience, we can assist you technically to help you choose the right project for your project.

Keep reading for more information on Rainscreen Cladding. Or you can download the Valcan brochure here. Request samples or get in touch here.