Aluminium CladdingLightweight and strong

Built to last the test of time

All-in-one cladding solutions

Non-combustible solutionsServicesExpertise, Support, & GuidancePartnerships

Working perfectly together

This is a block of text. Double-click this text to edit it.

VitraVerse

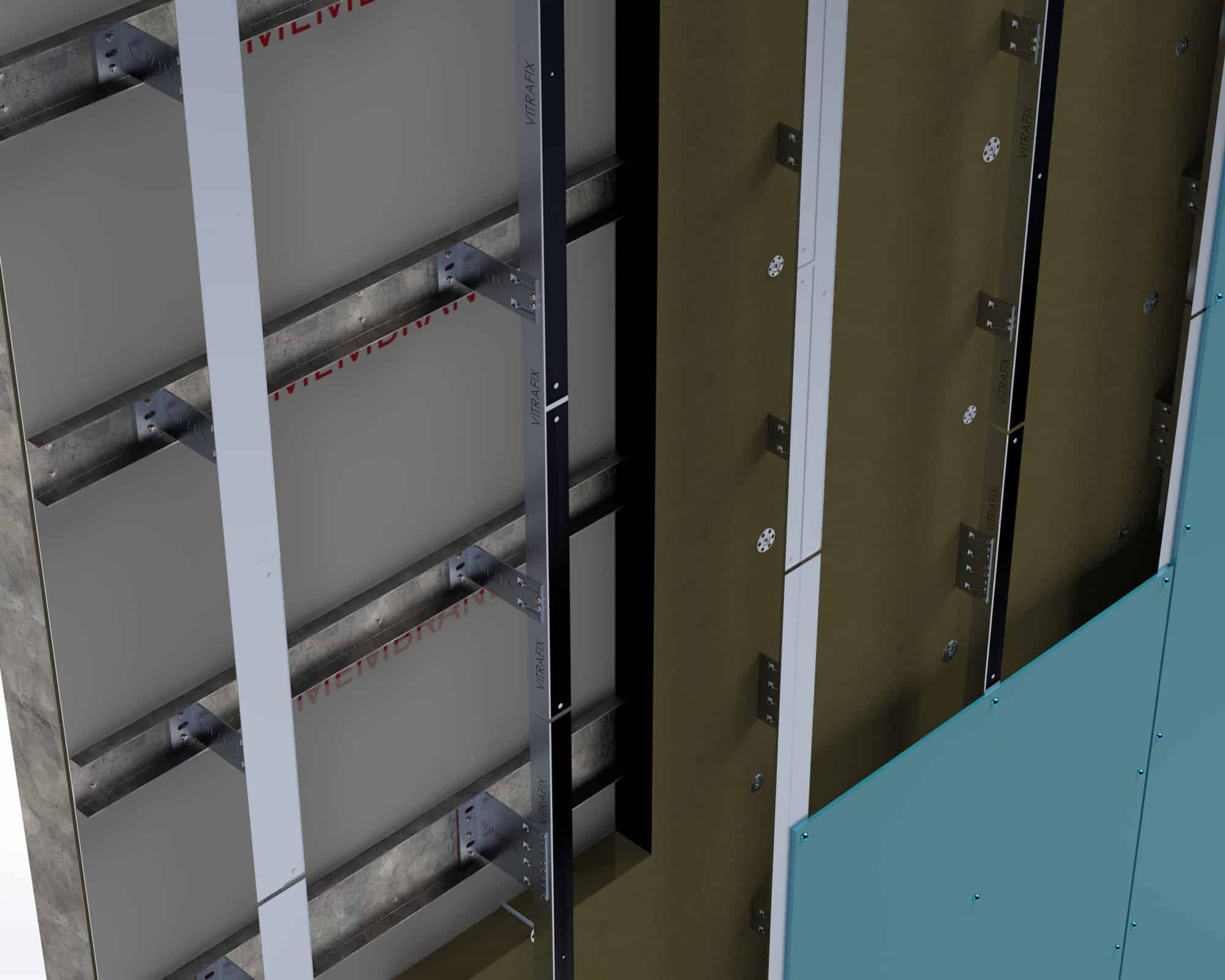

Complete Cladding Systems FrontekA1 | Extruded Porcelain Cladding

FrontekA1 | Extruded Porcelain CladdingSolidSafe®

A1 | Aluminium CladdingInstallers:

Join our Installer Partner NetworkFind a Local Installer

On-site installer checklist

Technical:

BIM Objects / SpecifiyCertification and AccreditationTypical DetailsFire Classification Reports

Breeam Scores

Information & Guides:

Accredited CPD SeminarsProduct BrochuresFabrication GuidanceInsightsStorage & Handling GuidanceMaintenance & Care Insurance Backed Guarantee Warranty Application Form

This is a block of text. Double-click this text to edit it.

Why Valcan?Certification and Accreditation Our Mission, Vision & Values

Support Complete Cladding SystemsCPD Seminars Valcan NewsBrochures

The Facade HUBSustainabilityOrder SamplesContact us

Support Complete Cladding SystemsCPD Seminars Valcan NewsBrochures

The Facade HUBSustainabilityOrder SamplesContact us

This is a block of text. Double-click this text to edit it.