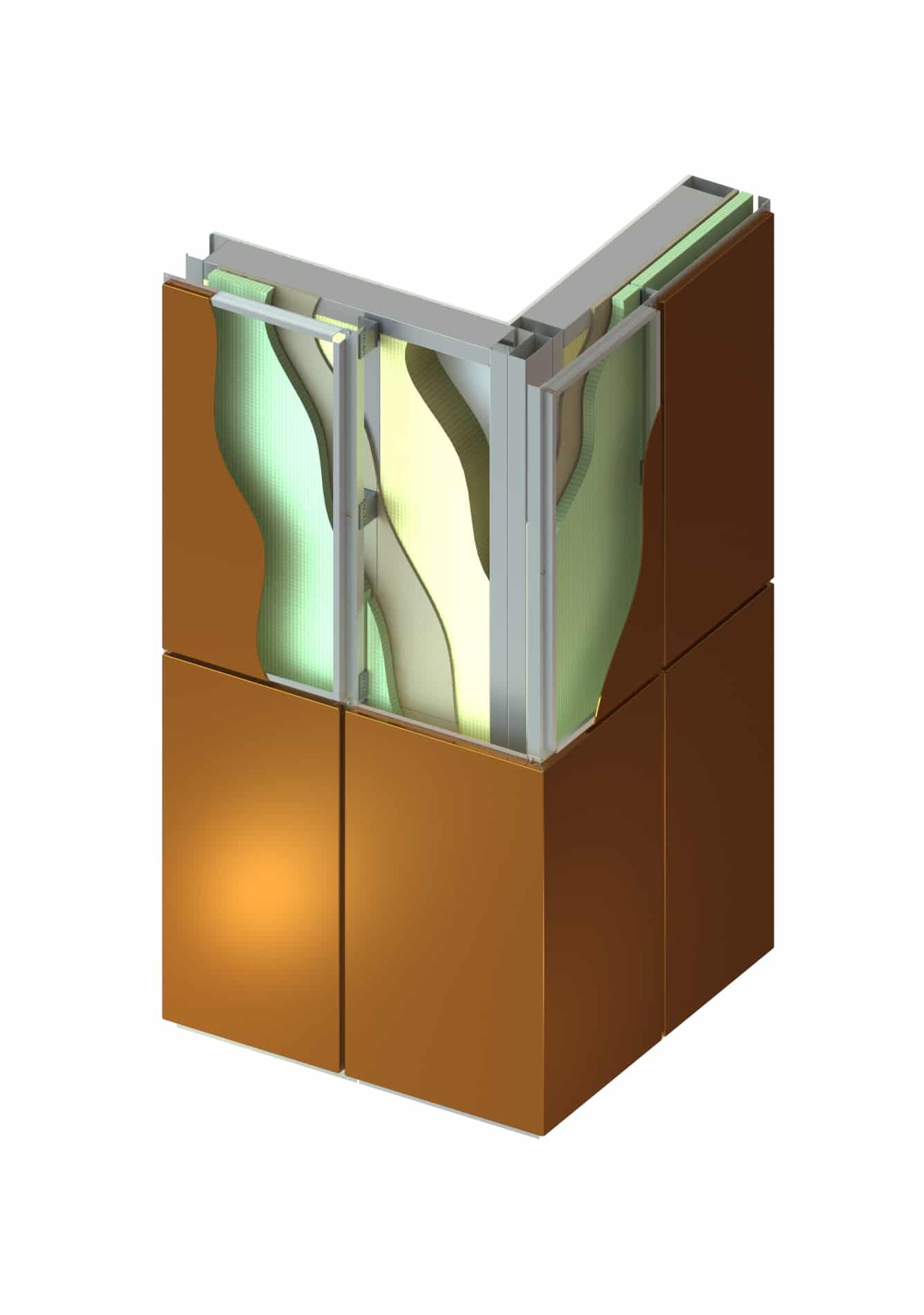

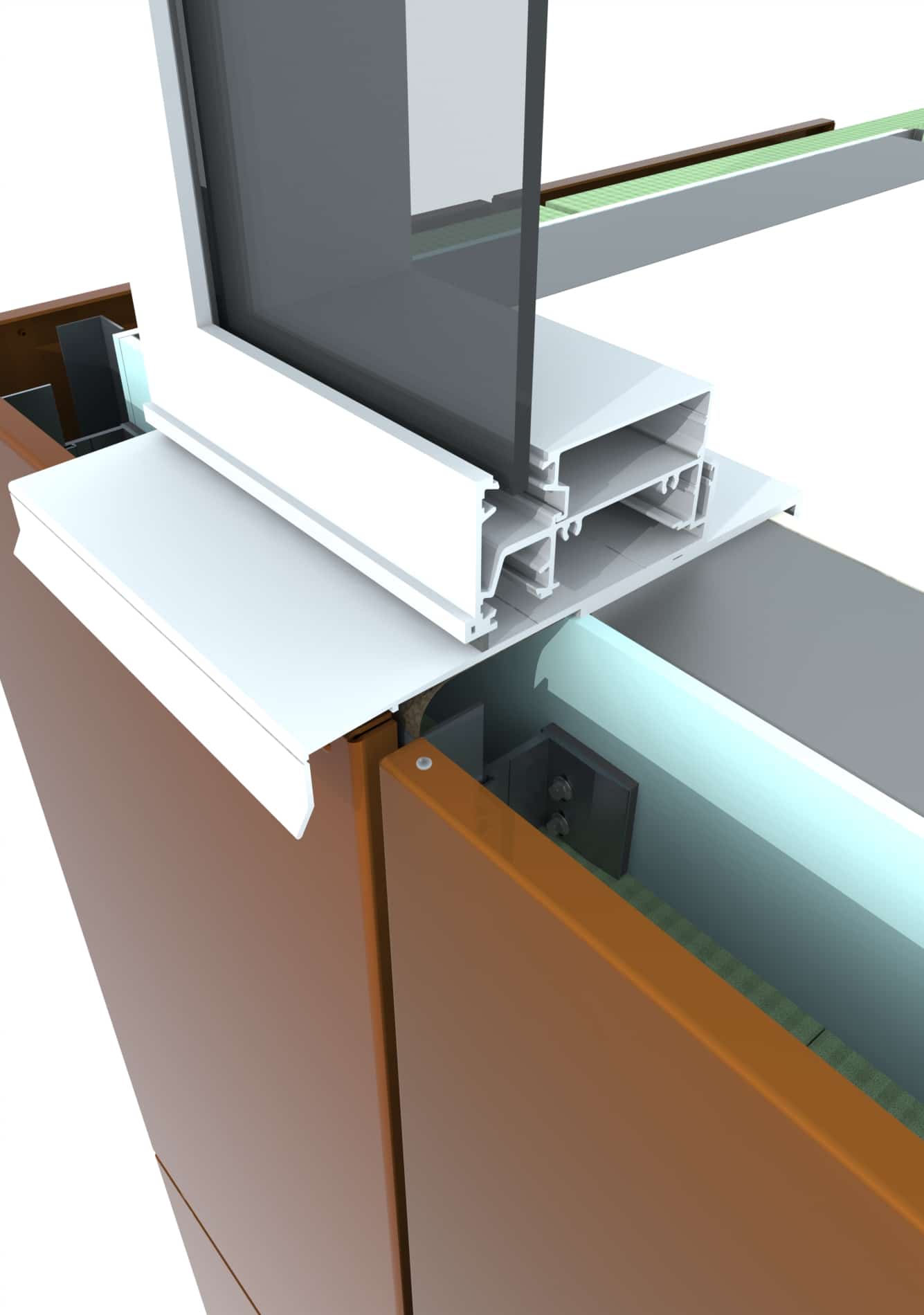

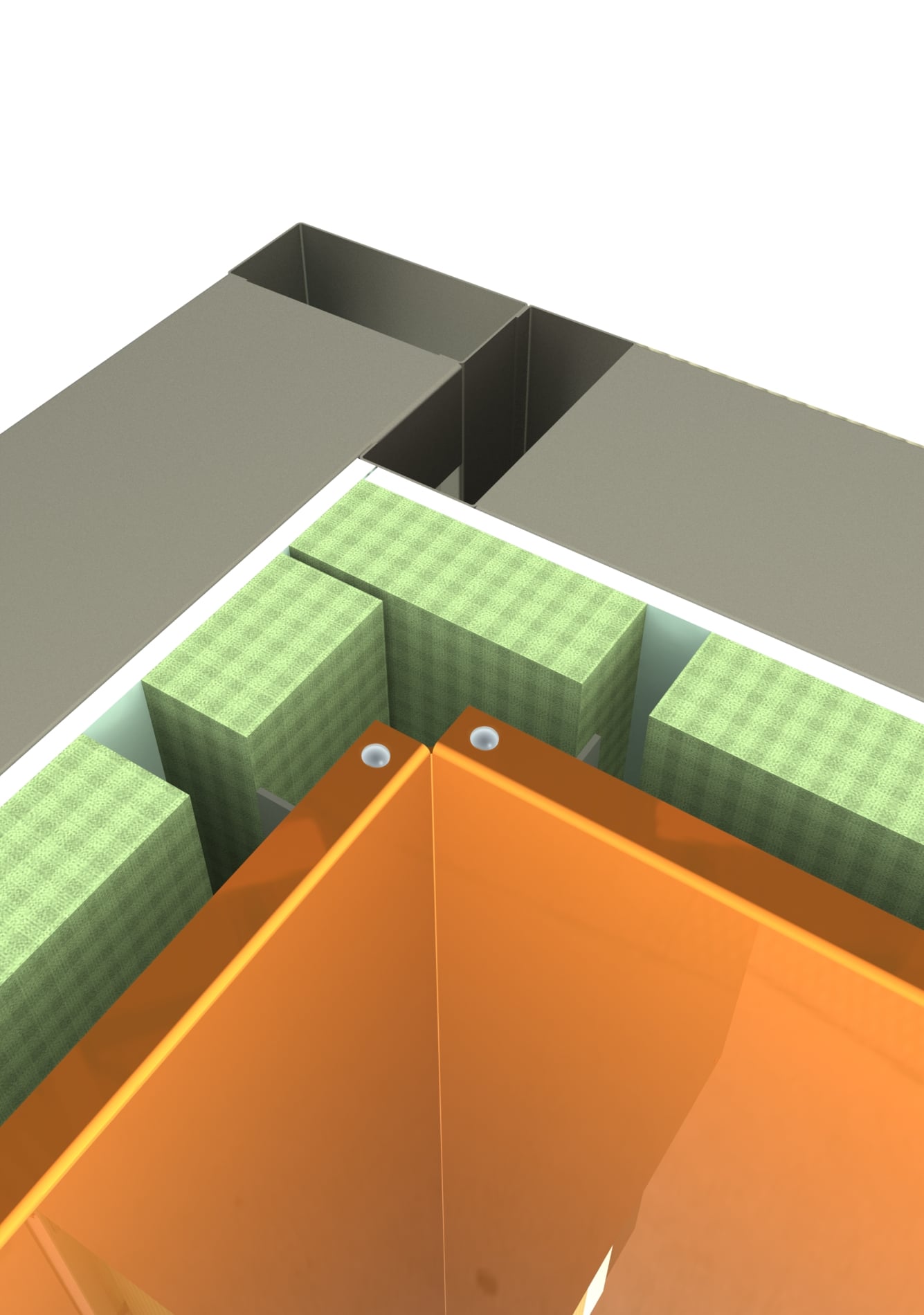

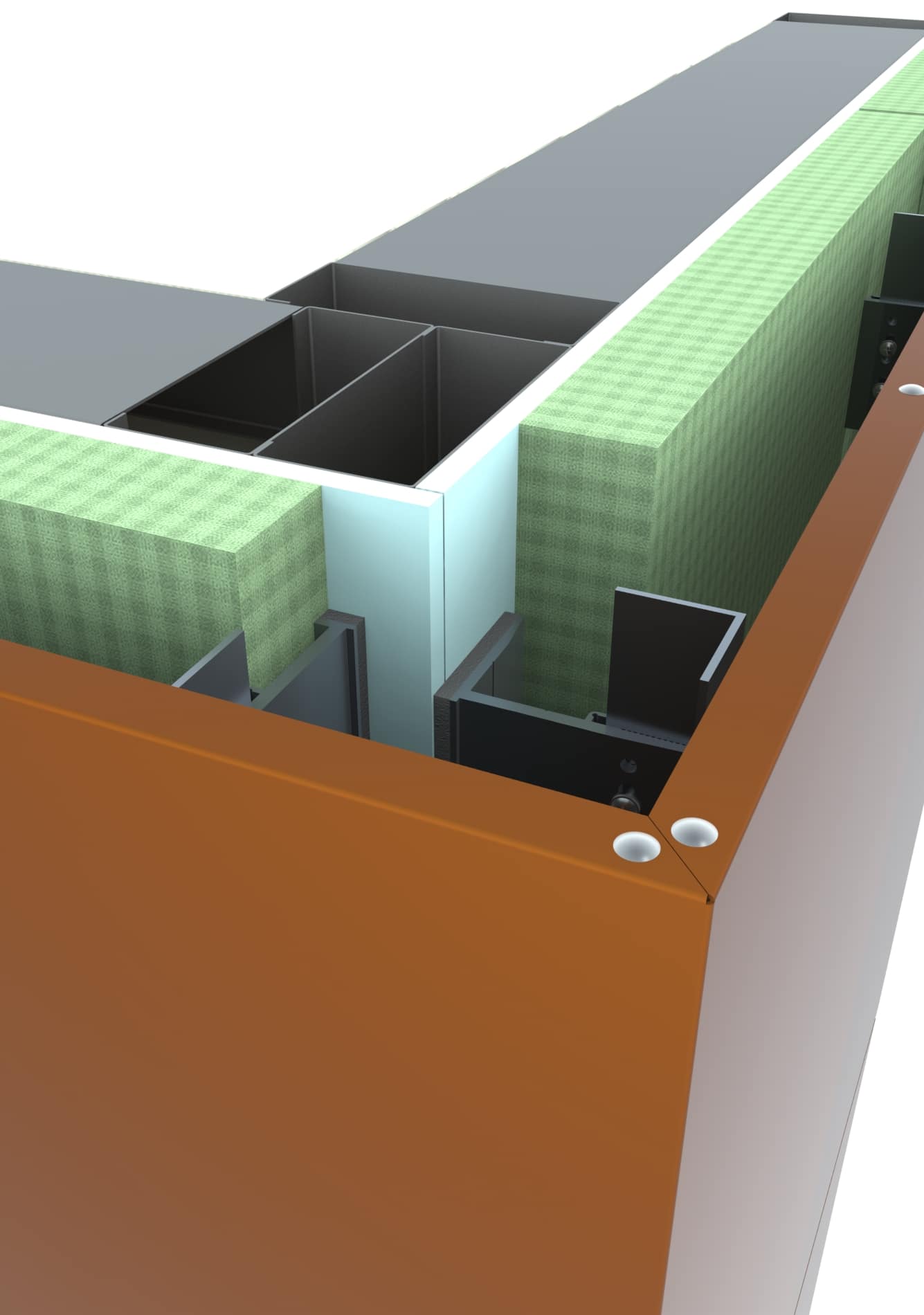

Aluminium CladdingLightweight and strong

Built to last the test of time

All-in-one cladding solutions

Non-combustible solutionsServicesExpertise, Support, & GuidancePartnerships

Working perfectly together

This is a block of text. Double-click this text to edit it.

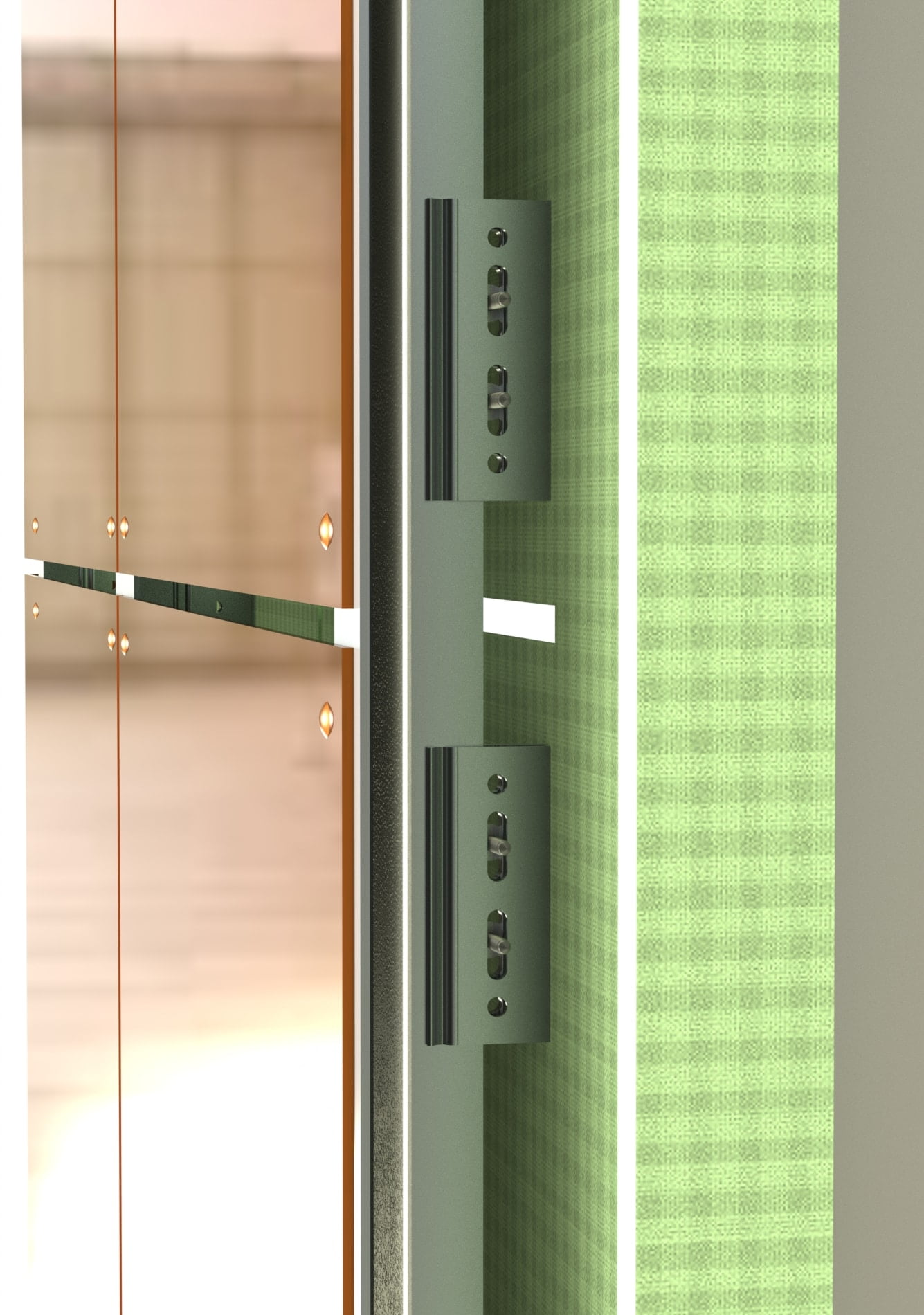

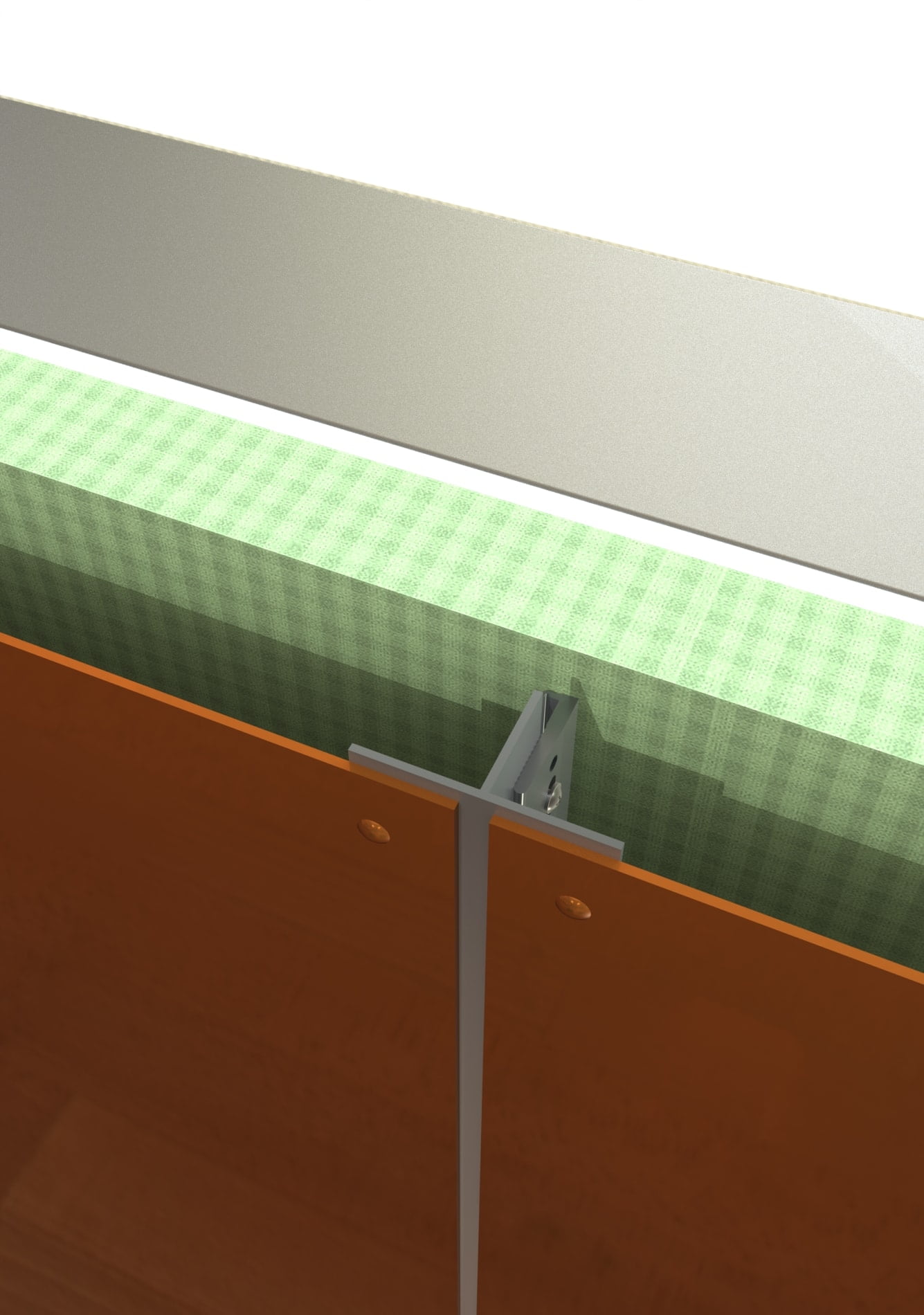

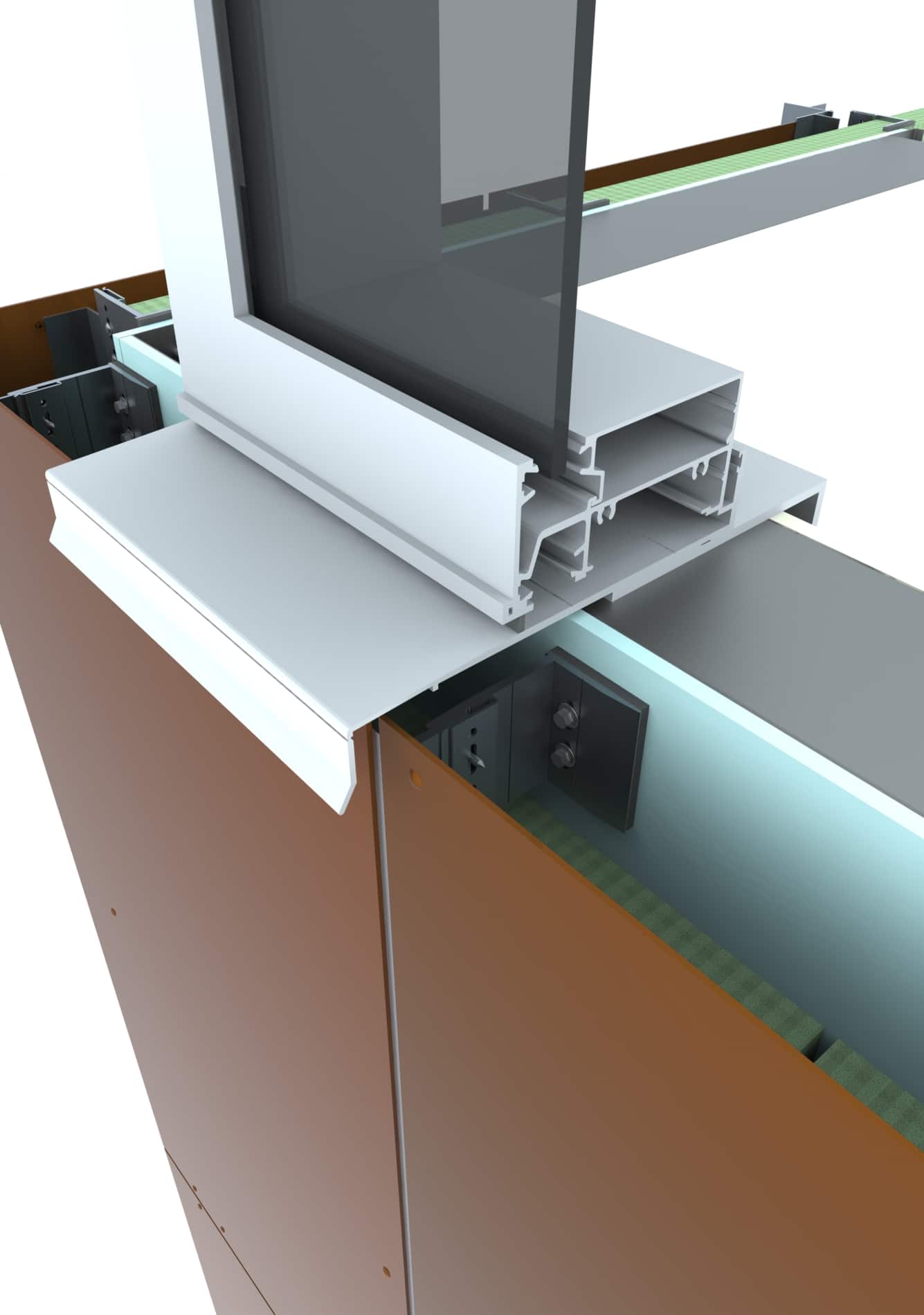

SolidSafe®

A1 | Aluminium CladdingNEW!

Installers:

Join our Installer Partner NetworkFind a Local Installer

On-site installer checklist

Warranty Application

Technical:

BIM Objects / SpecifiyCertification and AccreditationTypical DetailsFire Classification Reports

Breeam Scores

Information & Guides:

Samples/Colour ChartsCPDsProduct BrochuresFabrication

InsightsSustainabilityStorage & Handling Maintenance & CareInsurance Backed Guarantee

This is a block of text. Double-click this text to edit it.